KYLflex® TPC-ET / TPEE heat resistant series are suitable for extrusion products due to their stable extrusion performance and high heat resistance.

Heat resistant series

Features

Rapid crystallization, easy to mold

Excellent chemical stability

Excellent ageing resistance

Good creep resistance

Good rebound resilience

Excellent electrical performance

Excellent heat resistance

Good wear resistance

High flexural modulus

Grade List

| Grade | Hardness | Melting flow index | Flexural Modulus | Tensile stength | Tensile elongation | Melting point |

| / | Shore D | g/10min | Mpa | Mpa | % | ℃ |

| L5505CH | 52 | 5 | 150 | 35 | 560 | 201 |

| L6005CH | 56 | 5 | 240 | 42 | 450 | 210 |

| L7205CH | 68 | 5 | 500 | 46 | 400 | 218 |

Main Applications

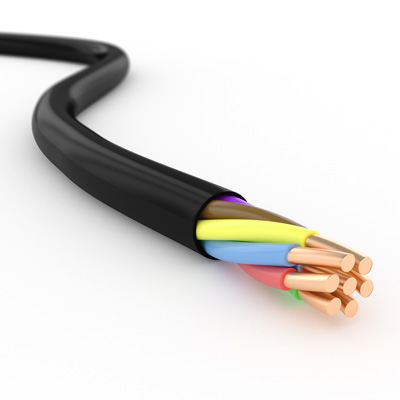

Cables & Wires

KYLflex® TPC-ET/TPEE has excellent flame retardancy and excellent high and low temperature resistance (-60℃-+150℃), high oil resistance, weather resistance, excellent creep resistance and fatigue resistance, excellent low temperature flexibility, low friction surface and good hydrolysis resistance. It is suitable for cables for electric, communications, transportation fields.

Hydraulic Hoses

TPEE hydraulic hoses has excellent properties such as high strength, high elasticity, corrosion resistance, grease resistance, high and low temperature resistance, and hydrolysis resistance. It is suitable for hydraulic hoses in machinery, aviation, aerospace and other fields.

Contact Us

Please fill in your email address and leave us a message, and our staff will contact you within 24 hours!