KYLflex® TPC-ET / TPEE blow molding series are suitable for blow molding products due to their good blow molding performance and high heat resistance, which can remain stable at high and low temperature.

Blow molding series

Features

Light weight

Excellent chemical stability

Low melting flow index, easy for blow molding

Oil resistance

Good creep resistance

Excellent ageing resistance

Can be used at 150℃ for long time

Good wear resistance

Good low temperature resistance (-60℃)

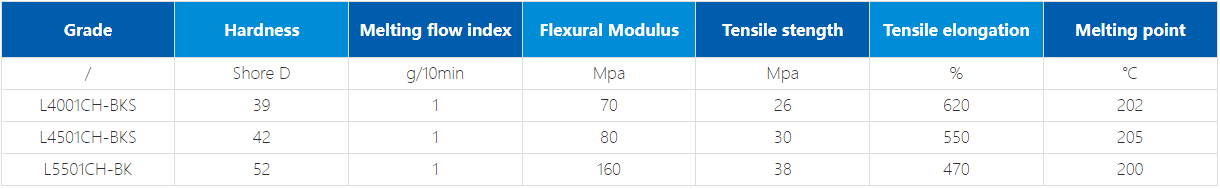

Grade List

| Grade | Hardness | Melting flow index | Flexural Modulus | Tensile stength | Tensile elongation | Melting point |

| / | Shore D | g/10min | Mpa | Mpa | % | ℃ |

| L4001CH-BKS | 39 | 1 | 70 | 26 | 620 | 202 |

| L4501CH-BKS | 42 | 1 | 80 | 30 | 550 | 205 |

| L5501CH-BK | 52 | 1 | 160 | 38 | 470 | 200 |

Main Applications

CVJ Boots

TPEE CVJ boots have excellent aging resistance, high and low temperature resistance, fatigue resistance, medium resistance and deformation resistance, which extends the service life of the boots, thereby reducing the emission of rubber waste.

Intake manifold

KYLflex® TPC-ET / TPEE has excellent mechanical properties and thermal stability, and can withstand the working conditions of high temperature and high pressure. With good chemical resistance, it can resist the erosion of various chemical media. In addition, TPEE also has good wear resistance and aging resistance, which can extend the service life of the intake manifold.

Contact Us

Please fill in your email address and leave us a message, and our staff will contact you within 24 hours!