KYLflex® TPC-ET / TPEE is suitable for injection and extrusion products due to their rapid mold-ability.

Injection and extrusion series

Features

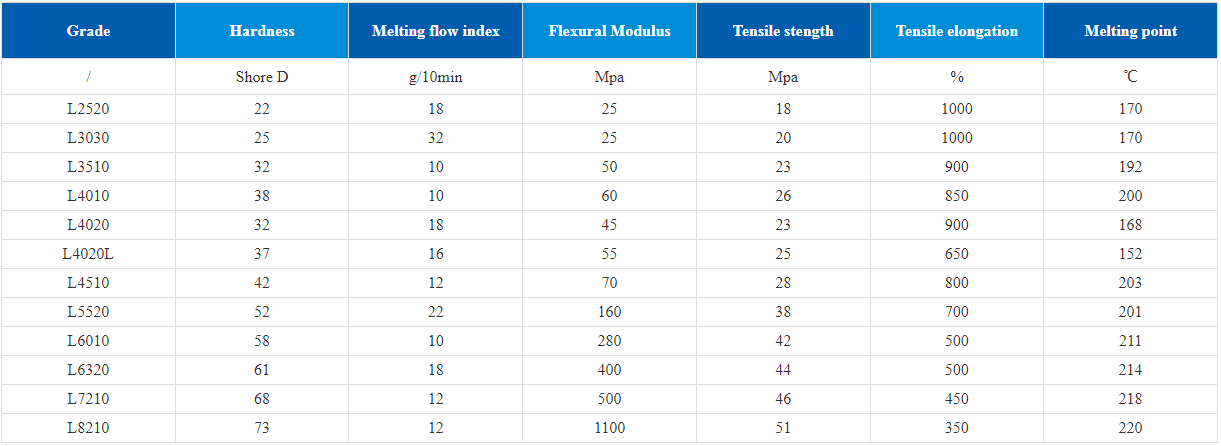

Grade List

| Grade | Hardness | Melting flow index | Flexural Modulus | Tensile stength | Tensile elongation | Melting point |

| / | Shore D | g/10min | Mpa | Mpa | % | ℃ |

| L2520 | 22 | 18 | 25 | 18 | 1000 | 170 |

| L3030 | 25 | 32 | 25 | 20 | 1000 | 170 |

| L3510 | 32 | 10 | 50 | 23 | 900 | 192 |

| L4010 | 38 | 10 | 60 | 26 | 850 | 200 |

| L4020 | 32 | 18 | 45 | 23 | 900 | 168 |

| L4020L | 37 | 16 | 55 | 25 | 650 | 152 |

| L4510 | 42 | 12 | 70 | 28 | 800 | 203 |

| L5520 | 52 | 22 | 160 | 38 | 700 | 201 |

| L6010 | 58 | 10 | 280 | 42 | 500 | 211 |

| L6320 | 61 | 18 | 400 | 44 | 500 | 214 |

| L7210 | 68 | 12 | 500 | 46 | 450 | 218 |

| L8210 | 73 | 12 | 1100 | 51 | 350 | 220 |

Main Applications

KYLflex® TPC-ET/TPEE has high elasticity and toughness, which helps to alleviate the vibration and impact during use, thereby protecting the stability and safety of the equipment. Its service life is twice as long as other pad materials, which significantly reduces railway maintenance costs.

KYLflex® TPC-ET/TPEE is featured with high elongation at break, flexural strength and flexural modulus; excellent low temperature toughness; low molding shrinkage; good mechanical strength. It can withstand burst testing and has no Bursts and fragments, keep the system in place and the cover can withstand front-end impacts.

KYLflex® TPC-ET/TPEE has excellent toughness and resilience properties, allowing it to withstand repeated bending and stretching without losing shape. It is uitable for glasses, hair brushes, etc.

KYLflex® TPC-ET / TPEE is featured with excellent wear resistance, flexural resistance, corrosion resistance, creep resistance, and aging resistance. It is suitable for wire (cable) sheath, optical fiber loose tube, connectors, etc.